“Our employees are very interested in what we’re doing in the field, it’s important to them. Many have told me that they chose to work at the company because they heard about our work in sustainability and that it is important for them to be part of an organization with an agenda like this.”

“We see our engagement in sustainability and the environment as our duty, an uncompromising commitment to make sure we do everything we can to improve our environment. This is our responsibility to the future – for all of us, for our children.”

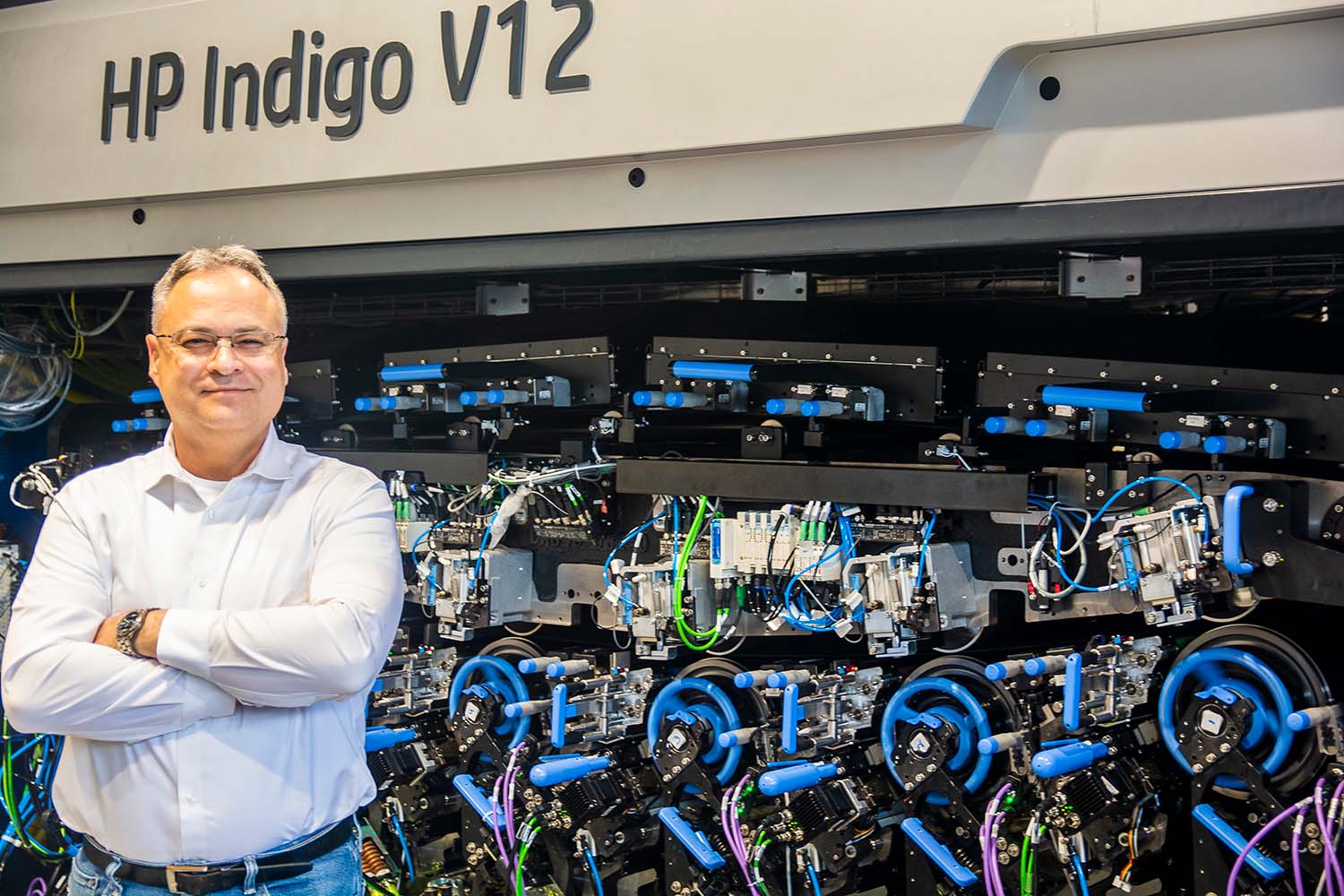

In recent years organizations have increasingly understood that they must be part of the global struggle for a greener future. At HP Indigo, it is a part of the daily routine and even an element of its core business. One salient advantage of digital printing is the ease of production in an environmentally-conscious way and the ability to use only the quantity of materials required.

Haim Levit, CEO of HP Indigo: “We see the commitment to sustainability and the environment in which we live as a must, it is an uncompromising commitment to make sure we do everything we can to improve our environment. It is our duty to the future - for all of us, for our children. The values of sustainability are embedded in the foundation of the company's operations and are integrated at every level, from our R&D labs to the production floor, in addition to the close engagement with our customers and their projects. We invest in sustainability not because we can, but because we are all responsible for building the infrastructure for our world’s future.”

HP Global devotes significant efforts to the entire issue of sustainability. For the past 20 years, the annual corporate responsibility report published by HP presents company achievements and sets far-reaching sustainability goals for the next decade, including goals for energy reduction, waste recycling, zero emissions and reuse of parts.

Keren Shinar, the sustainability manager for the environmental group at HP Indigo, explains that at the company, sustainability consists of several factors: society, community and occupational diversity. “Up until a decade ago, everyone was talking mainly in terms of linear economics - production, use and disposal,” says Shinar. "In the past decade, the concept of a circular economy has become more powerful. As part of its approach to the circular economy, for years HP Indigo has planned its products in advance and considered how to reuse their different parts. “For each of our products we consider which parts we can reuse, how to do so, and how to design them ahead of time to make recycling them easier. For example, many of the parts in our products are made of metal. It's a material that will last for many years if used properly, and it makes no sense to throw it away,” says Shinar.

HP collects the unusable parts of the machines it manufactures from its global customers, transfers them to its repair centers, recycles and reuses them as spare parts. The company employs many other measures to further promote sustainability. This is how HP Indigo conducts a comprehensive assessment on ways to reduce its carbon footprint, starting with production. According to Shinar, the company has taken on ambitious environmental goals. Last April, HP set its targets for the next decade, which include: 75% of the weight of products shipped to customers will be made of recycled materials; energy consumption will be reduced by 50%; and 100% recycling for all waste streams in factories over the next five years.

“Beyond product design and the reuse of parts, we look at other aspects of the value chain. Can we reduce the amounts of energy and waste during production? And how can we optimize transport of our products? For example, we prefer sea delivery to air delivery. It means we must plan correctly but those who plan well waste less.”

Passing it on

“Our employees are very interested in what we’re doing in this field, it’s important to them,” says Shinar. “Many decided to work at the company because they heard about our efforts to promote sustainability, which is a key reason that makes them want to be a part of this organization.”

One way that the company tries to reduce its environmental footprint is through carbon balancing. The company measures the amount of CO2 that is produced during operations, from material mining to production to transportation. “We balance this amount through different environmental and social projects, such as support and funding for solar panel installations in youth villages and local councils,” says Shinar. “We make sure to fund the installation of these panels for entities that wouldn’t do so without us.”

At the same time, the company operates in additional channels, with public entities and academia. “We work with local authorities and government ministries, such as the Ministry of Environmental Protection, to help the entire industry progress to a better place and to use elements from the circular economy,” says Shinar, “and with academia we work to advance research and transfer knowledge to students. We put our money where our mouth is and believe in our ability to lead the industry to real change.”