See how small brands can achieve a big brand presence

HP Indigo is helping flexible packaging converters go digital and thrive in the new, on-demand market

In the ultra-competitive consumer packaged goods (CPG) market, the only constant is change. Consumer tastes evolve, brands adapt, and new products emerge. Today, the pace of change is accelerating like never before, intensified by the COVID-19 pandemic and influenced heavily by the dynamic, increasingly personalized experience of the digital world. From shopping to social platforms, the continuous stream of customized, on-demand content is recalibrating the expectations of consumers, and it’s also inspiring the next generation of CPG entrepreneurs.

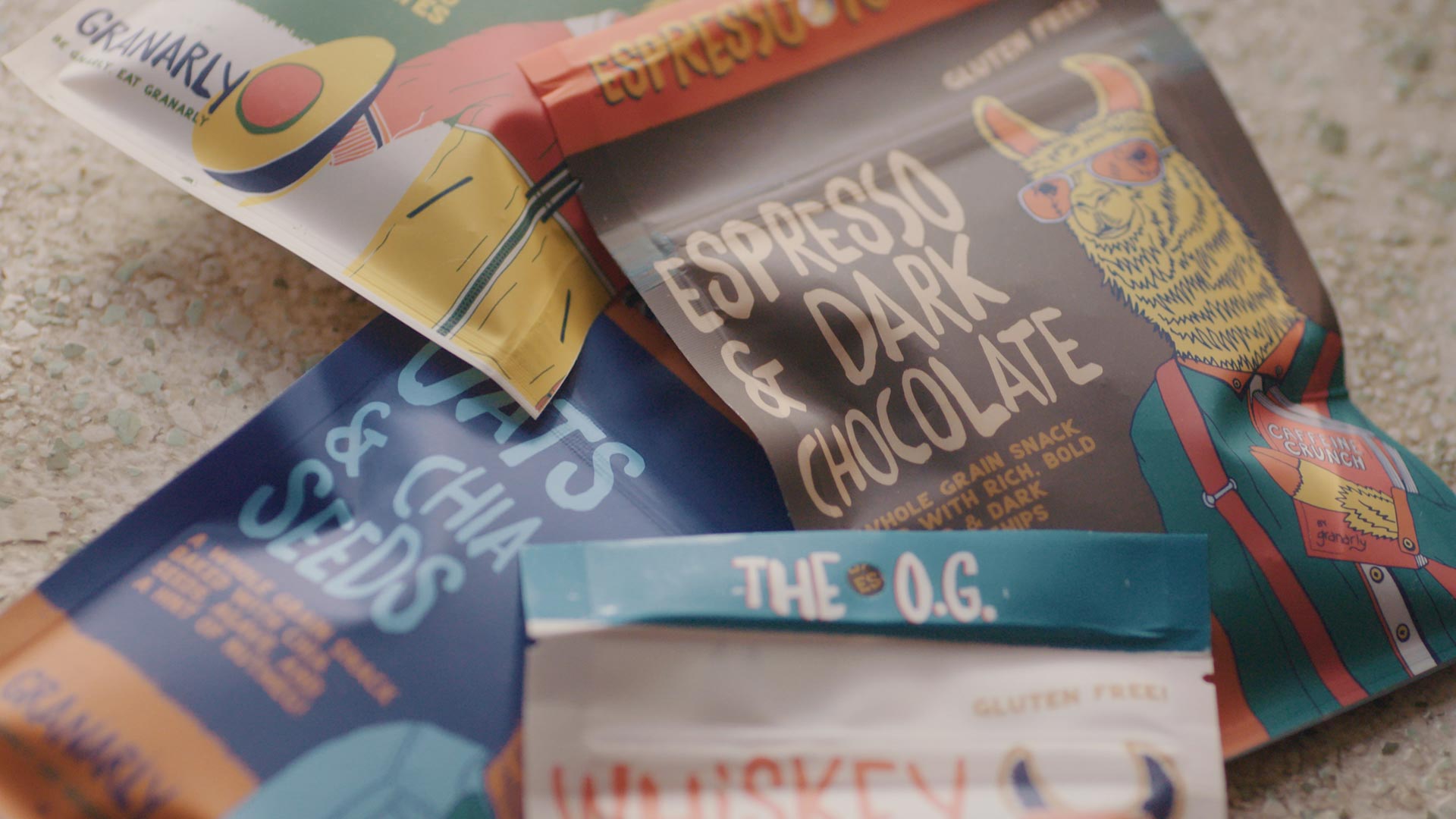

Craft brands are on the rise. Whether born out of years of planning or sparked organically out of quarantine boredom, upstart artisans are seeking to carve out their own niche in today’s fragmented marketplace. These are often premium, small-batch alternatives, insisting on high-quality ingredients and sustainable practices. They may be passion projects or mission-driven companies, and they share an uncompromising commitment to quality that extends to every aspect of their brand—including packaging.

Why go HP Indigo?

This emergence of high-value craft brands in the CPG marketplace creates tremendous opportunity for flexible packaging converters. To fully capitalize, however, you need technology that’s nimble enough to meet the speed, specialization, and sustainability requirements these brands demand. To thrive in today’s flexible packaging market, you need to go HP Indigo.

“Digitally printed flexible packaging is indeed an untapped market. Less than 1% of flexible packaging today is produced digitally,” says Carl Joachim, co-founder and CMO of ePac Flexible Packaging. “We started [the company] with one HP Indigo 20000 [Digital Press]. We were offering extremely high-quality graphics. And we were offering 10-day turnaround, in an industry that was accustomed to six-week turnaround.” And longer wait times weren’t the only drawback of craft brands’ experiences pre-Indigo. Required high-quantity orders, increased costs, limited product options, and international production and shipping were all part of the packaging process.

Powered by HP Indigo digital presses, converters like ePac have been propelled into the digital age, becoming champions for craft brands seeking to disrupt the CPG landscape. And in doing so, they’ve unlocked lucrative new revenue streams for their business. Their success in this emerging market demonstrates the transformative impact of digital flexible packaging. It’s a technology that you can truly build a business around, and even big players like Amcor are taking notice—proving that the future is digital printing with their recent $15 million investment in ePac.

The HP Indigo 25K Digital Press is the only field-proven solution for digital flexible packaging. Featuring the widest color gamut and white portfolio,¹ this press empowers packaging converters to consistently meet the most stringent brand standards and deliver gravure-matching quality across a wide range of applications. With more than 250 presses installed in more than 51 countries, emerging brands are making an unforgettable first impression with consumers and stepping into the CPG market with confidence, knowing that their packaging is pixel perfect.

“Right away I get comments on how beautiful my packaging is and how the colors stand out. It has transformed my business,” says Jessica Wuesthofen, founder of Imperfekt Bites in Austin, TX.

Flex into a more profitable future

Digital flexible packaging from HP Indigo enables converters to completely reinvent their value proposition with a combination of speed-to-market, customizable short runs, and eye-catching quality that others can’t match. The most efficient and sustainable way to produce on-demand flexible packaging, these digital presses generate higher margins by more quickly completing jobs that aren’t typically profitable with conventional production. Take on ultra-short runs of highly personalized designs, and take advantage of the growing need for on-demand production. With innovations like cutting-edge Liquid Electrophotographic (LEP) technology, you can tap into endless opportunities in this growing market. And with the comprehensive support of the HP ecosystem, you can become the ultimate packaging partner for emerging and established CPG brands. And with Spot Master—a feature that increases color consistency through greater automation and less waste—you can reduce the time spent on color and boost productivity by more than 25%.

Go from file to pouch in days

The HP Indigo competitive advantage goes beyond faster delivery, higher-quality printing. It enables you to become an end-to-end, file-to-pouch packaging partner for your customers. The HP Indigo Digital Pouch Factory is a unique ecosystem of printing, lamination, and pouch-making solutions supported by world-leading vendors, and it’s revolutionizing the flexible packaging industry for converters and brands alike. By enabling greater customization, sustainability, and supply chain efficiency, the Digital Pouch Factory is helping converters deliver any size job, just in time, more profitably than ever.

“If I come up with an idea, I can have it out and on the shelf and rocking and rolling in 15 days,” says Dustin Gersch, founder and owner of Paleo Powder Foods. “For someone to be able to give that to me as a startup, it’s just been huge.”

For Rootree, a leading converter of digital sustainable packaging, integrating HP Indigo solutions has empowered them to do more for their customers with fewer resources. With only seven employees, they’ve built a Digital Pouch Factory setup of two HP Indigo 20000 Digital Presses, one Pack Ready Laminator, one slitter, and one pouch machine to achieve extraordinary productivity and output—63 SKUs, 200,400 pouches, and 12,300 meters of rollstock on a typical day.

“Rootree uses the HP Indigo [Digital Pouch Factory] to really help us grow our sustainable packaging business,” says Rootree CEO Philippe St-Cyr. “It just allows us to grow at a rapid pace, and take on a lot of new accounts.”

Sustainability: More than a trend

For packaging innovators like Rootree and eco-conscious craft brands, sustainability is more than a buzzword or a green sticker on a pouch. It’s a core principle and a requirement for business success. So to help realize the vision of a more eco-friendly future, HP Indigo makes it simple for flexible packaging converters to print only what they need and integrate sustainability measures at every stage of the value chain—enabling brands to print whatever they’d like, whenever they want.

With no plates or cylinders, plus the ability to print on recycled and biodegradable media, digital flexible packaging from HP Indigo reduces the environmental impact of printing by 40-60% compared to flexo, and 60-80% compared to gravure.² Indigo-printed pouches received high scores of 90% and above in recyclability tests certified by CYCLOS HTP, and they’re food-packaging compliant with EU and FDA regulations.³ Plus, HP Indigo ElectroInks support home and industrial composting.

“With such a strong foundation and partnership with HP Indigo, I believe that we have the ultimate recipe for what packaging is going to be in the future,” Philippe St-Cyr of Rootree says.

Flex for the future. Start now.

As consumer lifestyles, preferences, priorities, and values evolve, a new generation of makers is emerging to fill the void. For Carl Joachim of ePac, that sense of possibility is what makes digital flexible packaging such an exciting and promising industry.

“There are literally thousands of these small-medium-sized brands, these young entrepreneurs that are looking to make a difference. Almost all of them turn into repeat customers. We learn every day about their challenges and know we can help them. And that is just the most gratifying feeling in the world.”

There’s never been a better time to join the digital revolution. Are you ready to flex? HP INDIGO FLEXIBLE PACKAGING

1. Compared to major digital printing competitors providing mid-web flexible packaging solutions as of November, 2019.

2. Based on a third-party life cycle assessment comparison to flexo and gravure that showed the HP Indigo 20000 Digital Press has low environmental impact on flexible packaging at economical jobs across all 13 environmental impact categories considered in the study. For details, see the technical white paper: Low environmental impact printing with HP Indigo Digital Presses, 2016.

3. Food products and packaging are a highly regulated sector, with varying requirements depending on where they are placed on the market. Therefore, converters are reminded to ensure that all materials utilized in the printing process are suited for the intended application and its conditions of use, and that the printing is performed in accordance with Good Manufacturing Practices. HP Indigo compliance with food packaging regulations: FDA, Title 21 of the Code of Federal Regulations for indirect food contact; Swiss Ordinance on Materials and Articles in Contact with Food, RS 817.023.21; EUPIA Guideline on Printing Inks Applied to the Non-Food Contact Surface of Food Packaging Materials and Articles (November 2011); Council of Europe Resolution ResAP (2005/2) for indirect food contact; Nestlé Guidance Note on Packaging Inks, exclusion lists for indirect food contact; German Food Law and Article 3 of the EU framework regulation 1935/2004, for non-food contact.