Clear all

HP Large Format printers help PSPs win higher-value jobs

HP Large Format printers help PSPs win higher-value jobs

Get an environmental sustainability edge with HP Latex technology

Get an environmental sustainability edge with HP Latex technology

When you’re choosing a large-format printer, always ask about the ink cartridges

When you’re choosing a large-format printer, always ask about the ink cartridges

HP explains the technology behind Latex ink

HP explains the technology behind Latex ink

Move up the value chain with new latex printers

Move up the value chain with new latex printers

Thermoforming: Expand into value-added applications

Thermoforming: Expand into value-added applications

What is a Plotter Printer?

What is a Plotter Printer?

HP DesignJet Plotter Printer Overview

HP DesignJet Plotter Printer Overview

Green Building Benefits: The Best Eco-Friendly Practices

Green Building Benefits: The Best Eco-Friendly Practices

Accelerate the production and installation of vehicle graphics with cutting edge printing solutions

Accelerate the production and installation of vehicle graphics with cutting edge printing solutions

Keeping up with a fast-moving retail market in vinyl graphics printing

Keeping up with a fast-moving retail market in vinyl graphics printing

Expand to cardboard, foam board, and acrylic print jobs with HP Latex R printer series

Expand to cardboard, foam board, and acrylic print jobs with HP Latex R printer series

HP Latex 630/700/800 Printer series vs UV Large Format Printers

HP Latex 630/700/800 Printer series vs UV Large Format Printers

Step-by-step guide for printing window graphics with HP Latex 800 W Printer

Step-by-step guide for printing window graphics with HP Latex 800 W Printer

How to print and install wallcoverings in 6 steps with the HP Latex 700/800 Printer series

How to print and install wallcoverings in 6 steps with the HP Latex 700/800 Printer series

How HP Latex can bring your business new opportunities in the high-margin printed décor market

How HP Latex can bring your business new opportunities in the high-margin printed décor market

Step-by-step guide for printing on canvas with HP Latex 700/800 Printer series

Step-by-step guide for printing on canvas with HP Latex 700/800 Printer series

Step-by-step guide for textile applications

Step-by-step guide for textile applications

Step-by-step guide for creating retail decoration using self-adhesive vinyl with HP Latex 700/800 Printer series

Step-by-step guide for creating retail decoration using self-adhesive vinyl with HP Latex 700/800 Printer series

Step-by-step guide on vehicle wrapping using self-adhesive vinyl with HP Latex 700/800 Printer series

Step-by-step guide on vehicle wrapping using self-adhesive vinyl with HP Latex 700/800 Printer series

Step-by-step guide on how to create stickers with the HP Latex 700/800 Printer series

Step-by-step guide on how to create stickers with the HP Latex 700/800 Printer series

See how you can transform spaces with the HP Latex R Printer series

See how you can transform spaces with the HP Latex R Printer series

Create amazing outdoor signage using ink adhesion with no primer

Create amazing outdoor signage using ink adhesion with no primer

Transform your space with vivid colors on transparent acrylic for indoor signage.

Transform your space with vivid colors on transparent acrylic for indoor signage.

Transform indoor decoration with the glossiest of all white inks on brushed aluminum

Transform indoor decoration with the glossiest of all white inks on brushed aluminum

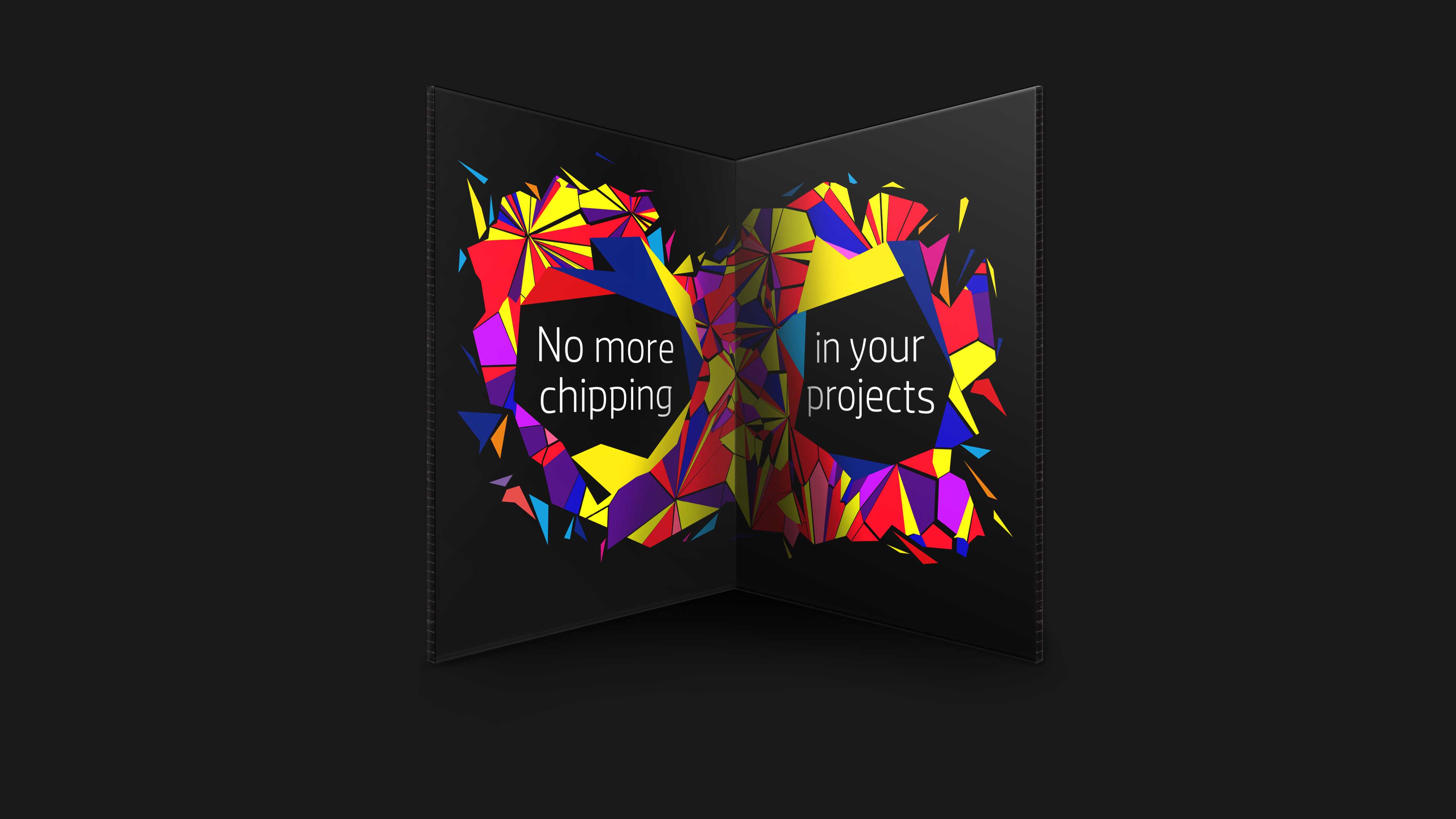

Discover how to print cardboard without ink cracking

Discover how to print cardboard without ink cracking

Learn how to transform any space with white foamboard for retail paneling

Learn how to transform any space with white foamboard for retail paneling

Discover true white that doesn’t yellow on PVC black foam.

Discover true white that doesn’t yellow on PVC black foam.

HP guide book: Learn how to print packaging in 6 steps

HP guide book: Learn how to print packaging in 6 steps

HP guide book: How to create indoor vacuum thermoforming applications in 7 steps

HP guide book: How to create indoor vacuum thermoforming applications in 7 steps

HP guide book: Learn how to print on acrylic boards (PMMA)

HP guide book: Learn how to print on acrylic boards (PMMA)

HP guide book: Learn how to print on aluminum composite panels in 5 steps

HP guide book: Learn how to print on aluminum composite panels in 5 steps

Step-by-step guide on how to gain access to the interior décor print market

Step-by-step guide on how to gain access to the interior décor print market

HP guide book: How to print window graphics on clear substrates in 5 steps with HP Latex R Printer series

HP guide book: How to print window graphics on clear substrates in 5 steps with HP Latex R Printer series

Step-by-step guide to create textile separation panels with HP Latex or HP STITCH

Step-by-step guide to create textile separation panels with HP Latex or HP STITCH

Printing high value vehicle wraps with 3MIJ 180 Cast Vinyl Film

Printing high value vehicle wraps with 3MIJ 180 Cast Vinyl Film

The HP Latex R Printer series top features explained in 30 minutes

The HP Latex R Printer series top features explained in 30 minutes

.jpg)

Learn everything you need to know about the HP Latex R Printer series

Learn everything you need to know about the HP Latex R Printer series

Transform almost any material in ways you never thought possible with the HP Latex R Printer series.

Transform almost any material in ways you never thought possible with the HP Latex R Printer series.

Learn how the HP Latex R Printer series offers the productivity of a belt system with the accuracy of a true flatbed

Learn how the HP Latex R Printer series offers the productivity of a belt system with the accuracy of a true flatbed

Learn how HP Latex R Printer series technology brings HP Latex image quality to rigid media

Learn how HP Latex R Printer series technology brings HP Latex image quality to rigid media

HP Latex 700/800 Printer series and Mimaki UCJV300-160 Printer series side-by-side comparison video

HP Latex 700/800 Printer series and Mimaki UCJV300-160 Printer series side-by-side comparison video

HP Latex 700/800 Printer series and Canon Colorado 1650 Printer side-by-side comparison video

HP Latex 700/800 Printer series and Canon Colorado 1650 Printer side-by-side comparison video

Learn how to amaze your customers with stunning image quality, vivid colors, and efficient turnaround times

Learn how to amaze your customers with stunning image quality, vivid colors, and efficient turnaround times

.jpg)

How can HP Latex 700/800 Printer series sharpen your sustainability edge?

How can HP Latex 700/800 Printer series sharpen your sustainability edge?

7 reasons to upgrade to the HP Latex 700/800 Printer series

7 reasons to upgrade to the HP Latex 700/800 Printer series

HP eBook: The top 5 fastest growing décor markets

HP eBook: The top 5 fastest growing décor markets

Printing high value wallcovering jobs with Korographics Abaco Beach

Printing high value wallcovering jobs with Korographics Abaco Beach

Printing on photo paper highlighting HP Professional Satin Photo Paper

Printing on photo paper highlighting HP Professional Satin Photo Paper

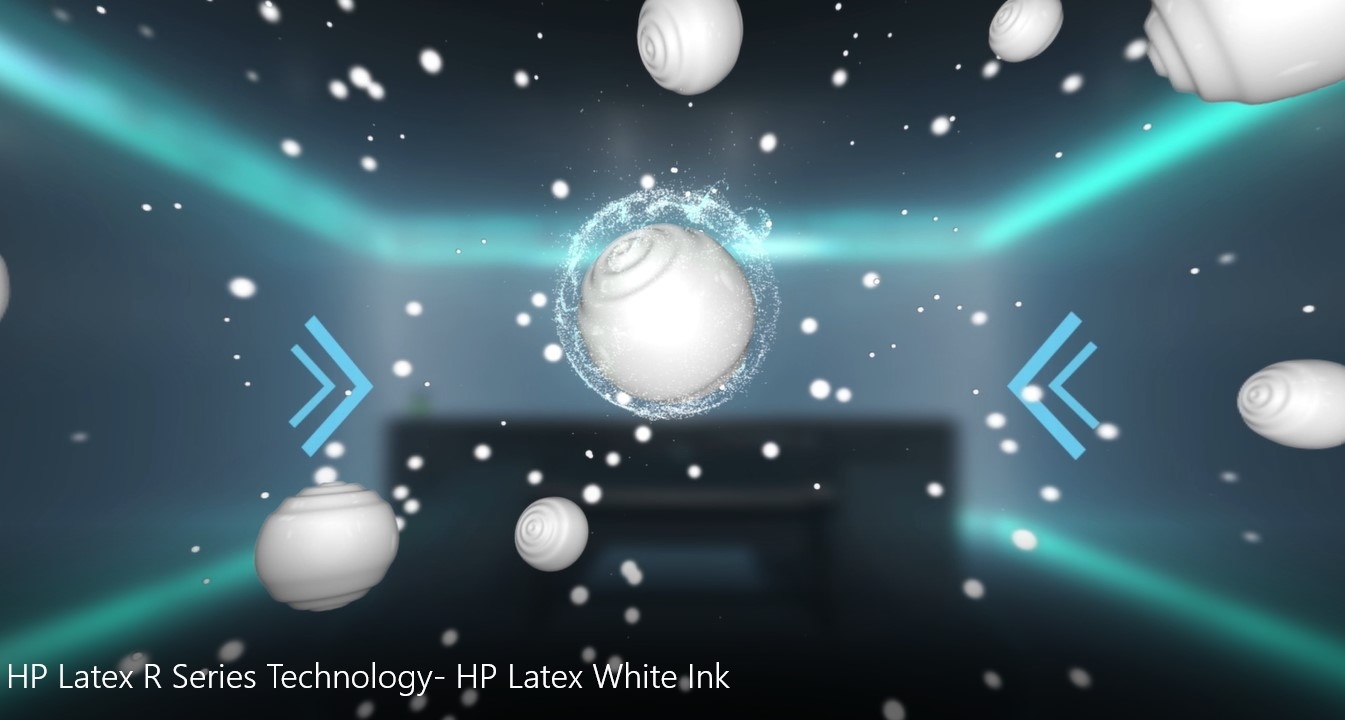

Learn about the world’s first white latex ink formulated by HP

Learn about the world’s first white latex ink formulated by HP

Sustainability: how to reduce your carbon footprint and improve your business

Sustainability: how to reduce your carbon footprint and improve your business

Learn how to sharpen your sustainable edge with HP Latex Technology

Learn how to sharpen your sustainable edge with HP Latex Technology

HP Latex Technology explained

HP Latex Technology explained

HP’s 2020 sustainable impact report

HP’s 2020 sustainable impact report

10 tips for a successful, sustainable print business

10 tips for a successful, sustainable print business

6 print jobs that can help you grow your margins

6 print jobs that can help you grow your margins

Eco certifications: What do they mean?

Eco certifications: What do they mean?

Latex R Printer series certifications: Discover how HP Latex Ink is better for the environment

Latex R Printer series certifications: Discover how HP Latex Ink is better for the environment

HP Large Format printers help PSPs win higher-value jobs

HP Large Format printers help PSPs win higher-value jobs

Get an environmental sustainability edge with HP Latex technology

Get an environmental sustainability edge with HP Latex technology

Beat your deadlines by working faster and smarter

Beat your deadlines by working faster and smarter

Move up the value chain with new latex printers

Move up the value chain with new latex printers

HP’s 2021 sustainable impact report

HP’s 2021 sustainable impact report

Expand your capabilities into the new décor trends your customers are looking for

Expand your capabilities into the new décor trends your customers are looking for

Create high quality visual displays and grow profit margins

Create high quality visual displays and grow profit margins

How print shops can gain business advantages with stunning canvas prints

How print shops can gain business advantages with stunning canvas prints

How to grow your business with white ink applications

How to grow your business with white ink applications

No results found

Built for what you do

Contact us

Request samples

Are you interested in seeing for yourself our print samples? Request your sample kit from our selected range.

Book a demo

Get in touch with us and we’ll schedule a printer demo, specifically catered for you what you’re looking for.

Talk with an expert

Would you like to speak with an HP product expert to learn more about HP Latex?

Stay up to date

Subscribe to Large-Format printing newsletter and keep up to date with our latest tech news.

Country/Region :

United States

Select Your Country/Region and Language

- Africa

- Afrique

- América Central

- Argentina

- Asia Pacific

- Australia

- Bangladesh

- België

- Belgique

- Bolivia

- Brasil

- Canada

- Canada - Français

- Caribbean

- Česká republika

- Chile

- Colombia

- Danmark

- Deutschland

- Ecuador

- Eesti

- España

- France

- Hong Kong SAR

- Hrvatska

- India

- Indonesia

- Ireland

- Italia

- Latvija

- Lietuva

- Magyarország

- Malaysia

- México

- Middle East

- Nederland

- New Zealand

- Nigeria

- Norge

- Österreich

- Pakistan

- Paraguay

- Perú

- Philippines

- Polska

- Portugal

- Puerto Rico

- România

- Saudi Arabia

- Singapore

- Slovenija

- Slovensko

- South Africa

- Sri Lanka

- Suisse

- Suomi

- Sverige

- Switzerland

- Türkiye

- United Kingdom

- United States

- Uruguay

- Venezuela

- Việt Nam

- Ελλάδα

- България

- Казахстан

- Србија

- Україна

- ישראל

- الشرق الأوسط

- المملكة العربية السعودية

- ไทย

- 中华人民共和国

- 臺灣 地區

- 日本

- 香港特別行政區

- 한국

©2025 HP Development Company, L.P. The information contained herein is subject to change without notice.